Strengths of Our PAILIEN

Our company is located in Dezhou City, Shandong Province, China. The company covers an area of more than 30,000 square meters, with more than 80 patents and honorary certificates, and more than 20 types of drilling rigs. The products are exported to many countries and regions around the world. Our company specializes in the production of various drilling rigs, such as exploration drilling rigs, core drilling rigs, pneumatic water well-drilling rigs, and reverse circulation drilling rigs, which are applied to drilling operations in various complex working conditions.

Various Certificates of Honor

Product Classification

Core Drilling Rig

The fully hydraulic core drilling rig is mainly composed of a hydraulic system, a power unit, a drill frame, a drill bit, a rotary device, a feed system, a coring device, an operating table, etc. The drilling depth range is about 100~3000m. It is divided into standard calibers such as BQ/HQ/NQ/PQ. It is mainly used for engineering surveys, geological surveys, mineral explorations, etc. The whole equipment is flexible to operate and has strong power.

Water Well Drilling Rig

Pneumatic water well drilling rigs are mainly composed of core components such as pneumatic systems, drilling tools, drill stands, control systems, etc. They can be used in water well drilling, farmland irrigation wells, emergency water supply and other scenarios. They mainly use pneumatic impact or rotary drilling methods and can adapt to operational needs in remote areas, drought or power-deficient areas.

Exploration Drilling Rig

Exploration drilling rigs are mainly divided into core drilling rigs, rotary drilling rigs, impact drilling rigs, etc. Our company mainly produces core drilling rigs. They are mainly used for drilling in the fields of environmental testing, geological exploration, engineering geological surveys, mineral resource surveys, etc., so as to obtain underground cores, soil samples or conduct in-situ tests. They are mainly used in geology such as granite and basalt, and use diamond rope to extract the core.

How to Custom Design the Right Exploration Core Drill Rig

- Clarify demand goals

- Working condition analysis

- Performance characteristics

- Technical drawings

- Three-dimensional experiments

- Prototype testing

- Phased acceptance

- Final acceptance

Our Factory Advantages

- Material screening

- International Certification

- Production Chain

- Technical Team

- Customization

- Fully certified

- Testing equipment

- R&D Capabilities

- Unannounced Audits

- Service

Drilling Rig Construction Site Drawing

Scientifically Selected Materials, Quality Assurance

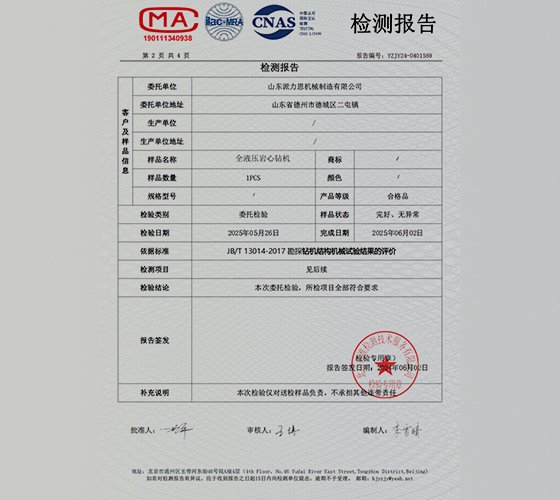

We will provide test reports for a wide range of materials to ensure that the products you purchase are reasonable and meet the inspection standards of the international market.

Comprehensive Quality Inspection

Before the drilling rig equipment leaves the factory, a third-party quality inspection will be carried out to ensure that each piece of equipment delivered to the customer meets international standards.

Testing includes appearance and structure inspection to ensure the integrity of the equipment; no-load operation, load testing, control system testing, etc.; safety performance testing, non-destructive testing, etc.